The oxygen concentrator was developed in the late 1970s as a medical device to provide a continuous and concentrated supply of oxygen to individuals who required oxygen therapy. The technology behind oxygen concentrators involves the principles of adsorption and pressure swing adsorption (PSA).

Discovery and Development:

Late 1970s: The practical development of oxygen concentrators was made possible by advancements in materials science, particularly the use of molecular sieves. These are materials with a highly porous structure that can selectively adsorb specific molecules while allowing others to pass through.

Technology Elaboration:

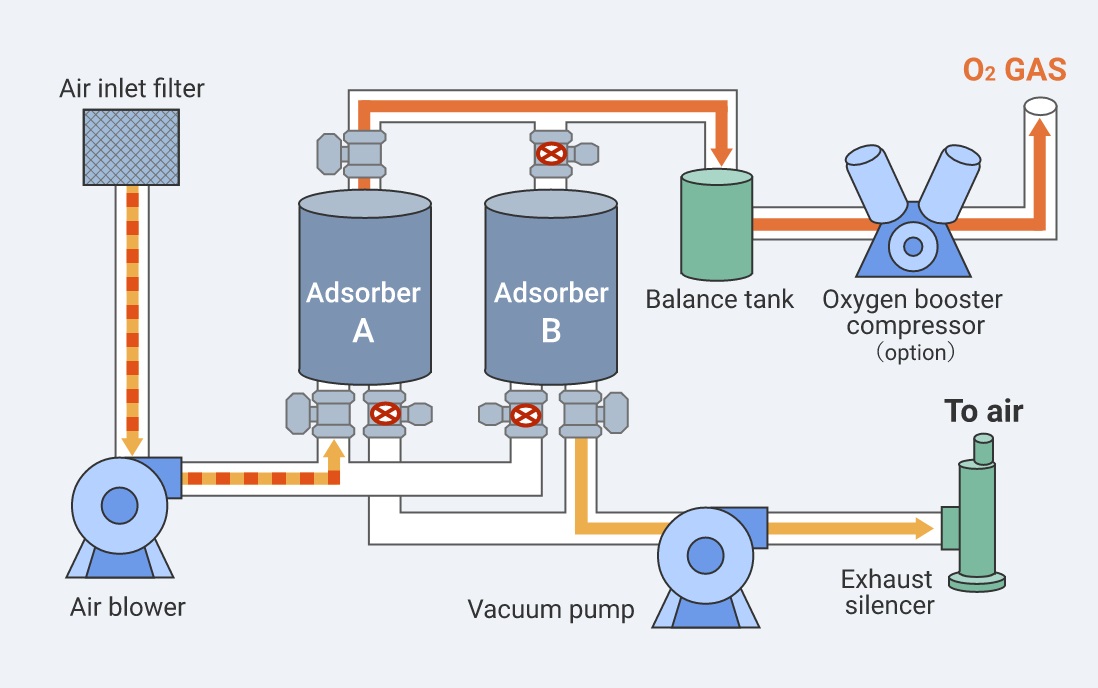

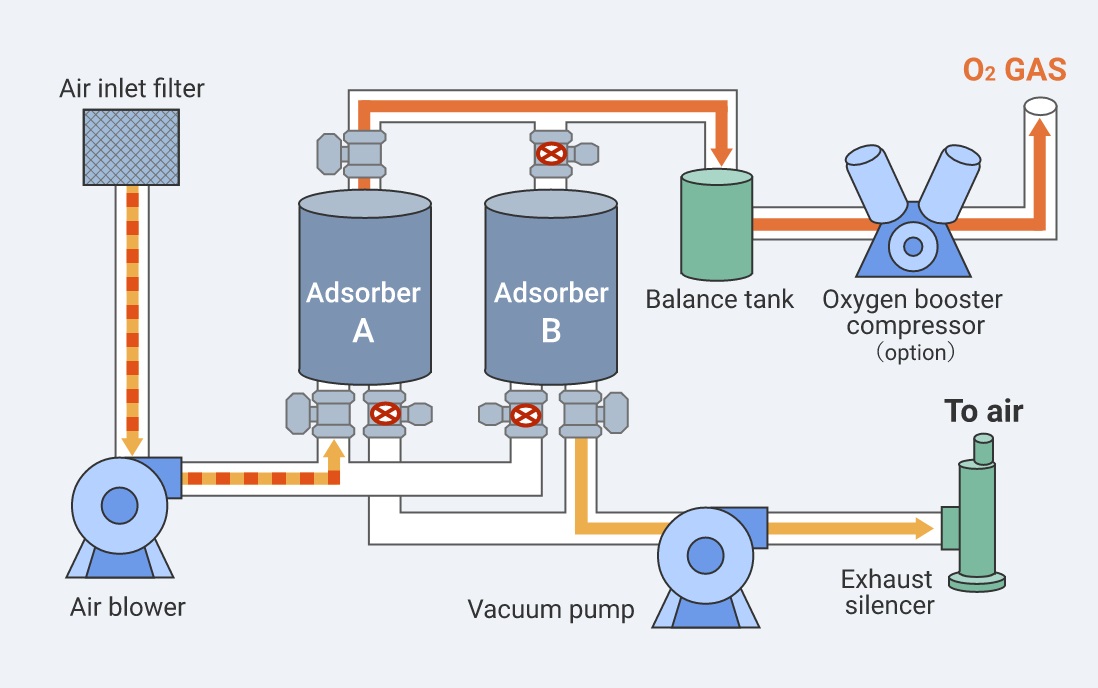

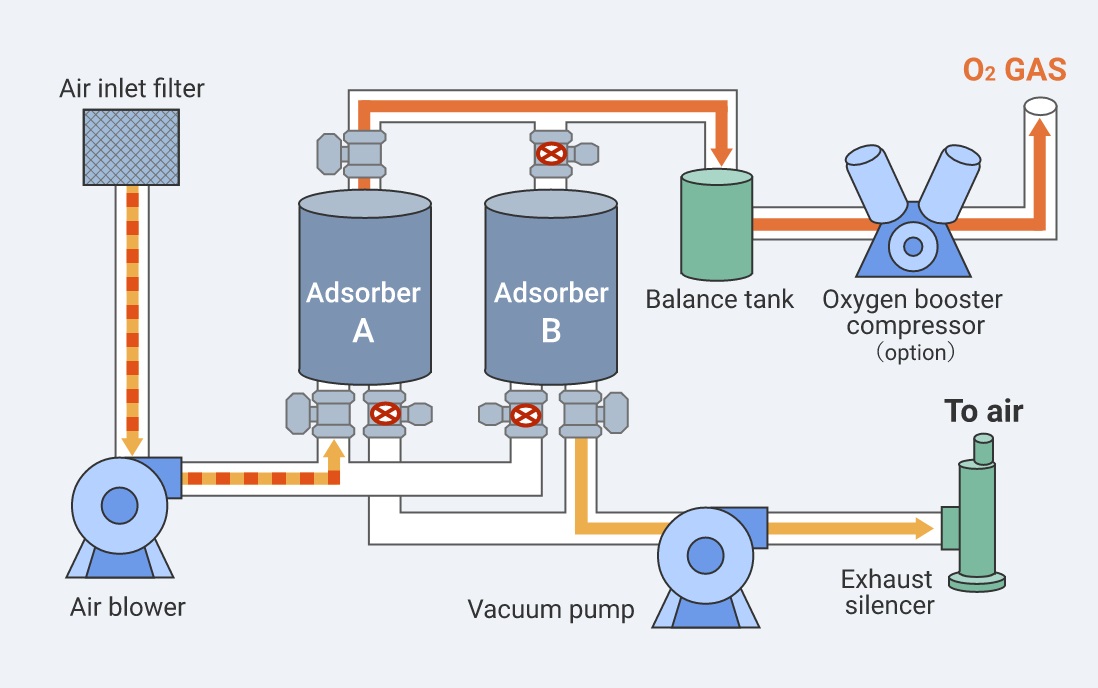

Oxygen concentrators work based on the principle of pressure swing adsorption (PSA), which involves several key steps:

Air Intake: The concentrator draws in ambient air from the surroundings, which consists of approximately 78% nitrogen, 21% oxygen, and trace amounts of other gases.

Air Filtration: The incoming air is often passed through a filter to remove larger particles and impurities. This ensures that the air entering the concentrator is clean and free from contaminants.

Adsorption Tower: The heart of the oxygen concentrator is the adsorption tower, which contains a bed of a specialized adsorbent material called a molecular sieve, typically made of zeolite minerals. Zeolites have a structure with tiny pores of a specific size that can trap and hold nitrogen molecules while allowing smaller oxygen molecules to pass through.

Adsorption Phase: During this phase, air is forced into the adsorption tower under pressure. The nitrogen molecules get trapped within the molecular sieve's pores due to their larger size, while the oxygen molecules pass through and are collected for use.

Desorption Phase: Once the adsorption tower is saturated with nitrogen, the pressure is released, and the nitrogen is released from the molecular sieve. This process is called desorption. The adsorbent is then ready for another cycle.

Oxygen Delivery: The concentrated oxygen collected during the adsorption phase is collected and delivered to the patient through a nasal cannula or mask. The oxygen delivered is typically around 90-95% pure, which is suitable for most medical applications.

Cycle Repetition: The adsorption and desorption phases are cyclic. While one tower is in the adsorption phase, another tower is in the desorption phase. This alternation ensures a continuous supply of concentrated oxygen.

Advantages of Oxygen Concentrators:

Portability: Oxygen concentrators are compact and lightweight compared to traditional oxygen cylinders, allowing patients greater mobility and the ability to continue their daily activities.

Cost-Effectiveness: Unlike oxygen cylinders that need refilling, concentrators use ambient air as their source, reducing the need for frequent resupply and lowering overall costs.

Continuous Supply: Oxygen concentrators can provide a continuous supply of oxygen as long as they have a power source, ensuring patients receive the necessary oxygen therapy without interruption.

Adjustable Flow: Oxygen flow rates can often be adjusted to meet the specific needs of individual patients.

In conclusion, the discovery and development of oxygen concentrators were driven by the need for a more convenient, cost-effective, and portable solution for delivering oxygen therapy to patients with respiratory conditions. The technology relies on the principles of pressure swing adsorption and the use of molecular sieves like zeolites to selectively adsorb nitrogen and deliver concentrated oxygen. This invention has significantly improved the quality of life for many individuals who require supplemental oxygen therapy.